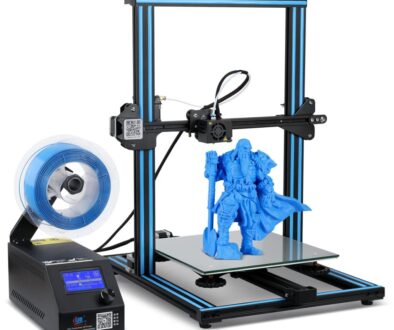

CAM/ CAD/ CNC Trainer

Untuk praktek pembelajaran pemakaian CAM dan CNC program.

Machine simulation includes real components like coolant, sound for machining operations and chips generation.

Workpiece setting and mounting. Three-dimensional measuring of workpiece after it is machined. Materials library, edit and insert new materials.

Database management tools and tools customization.

The turret can be configured for 4, 8 or 12 stations (front or rear). The automatic tool changer for the machining center can be setup horizontally or vertically. Use virtual measuring tools: edge finder, feeler gauge, micrometer, calipers etc.

Recording and playback system. Operation process recording and replay in AVI format. Support ISO- 1056 preparatory function codes (G codes), assistant function codes (M codes).

G-code debugging tool. Capability to simulate canned cycles, macros and the inclusion of parameters.

polar coordinate programming, G02, G03 spiral interpolation. Support for custom code and cycles in different NC systems. Simulates post processed files produced by CAM.

Electronic hand wheel available. Modes JOG, MDI, EDIT, SINGLE BLOCK, AUTOMATIC, DRY RUN, STOP CYCLE, CYCLE START, EMERGENCY etc.